0086 15335008985

電動フランジボールバルブの技術的特徴と応用解析

動作原理の分析

の 電動フランジボールバルブ 独自の動作機構を備えており、その中心となるのは、同じ 90 度の回転動作と昇降動作です。その軸上には円形の貫通穴またはチャネルがあり、これは非常に重要な構造です。重要な要素として、流路開口部に対する球面の比率が慎重に設計されています。球体が90度回転すると入口と出口が球状となり、媒体の流れを効果的に遮断します。通路を開く必要がある場合は、球体を逆方向に回転させて円形の貫通穴をパイプラインに合わせ、媒体がスムーズに通過できるようにします。必要な回転角度は 90 度だけで、小さなトルクの作用でバルブをしっかりと閉じることができます。バルブ本体の完全に等しい内部空洞は、媒体の流れに対して理想的な低抵抗の直線的な流路を構築し、エネルギー損失を軽減します。

機能特性表示

ボールバルブは一般に、媒体のオンオフを制御するためにパイプラインを直接開閉するのに適していると考えられています。電動フランジボールバルブはこの基本機能を優れた性能で発揮し、パイプライン内の媒体の切断や接続を迅速かつ正確に行うことができ、さまざまな工業プロセスの安定稼働を確実に保証します。技術の継続的な進歩と業界ニーズの継続的な進化に伴い、ボールバルブの機能も拡張され、現在では電動フランジボールバルブも絞り機能や流量制御機能を備えた設計になっています。電動アクチュエータを精密に制御し、ボールの回転角度を調整することでバルブ開度を柔軟に変化させることができ、流体の流れを正確に制御し、複雑な使用条件下での高度な流量管理のニーズに応えます。

製品の重要な機能

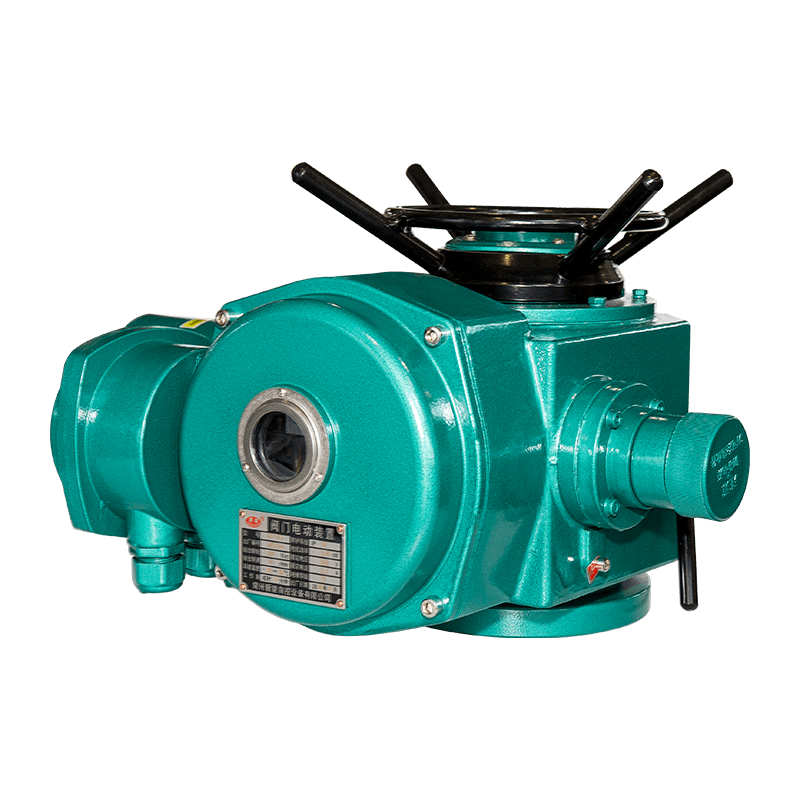

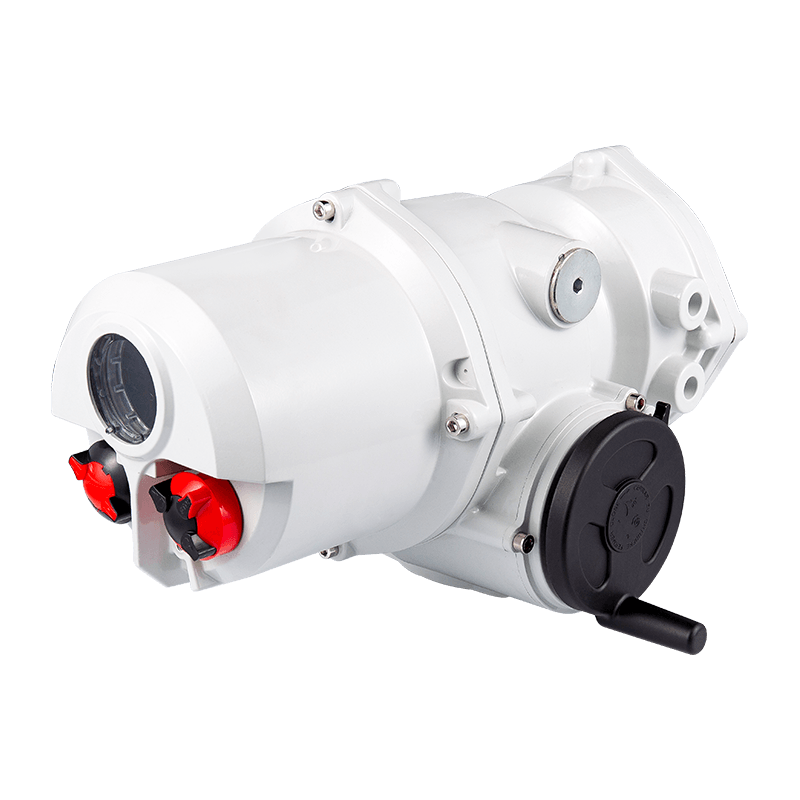

の electric flange ball valve has a compact overall structure and a small footprint, which has significant advantages in installation environments with limited space. It can be easily adapted to dense industrial plants and building facilities with strict requirements on space layout, bringing great convenience to engineering design and installation. The operation process is simple and easy to understand. With the help of electric actuators, operators can easily open, close and adjust the valve remotely without having to go to the site for manual operation, saving labor costs and operation time. The maintenance of this product is also relatively convenient. The structure of each component is clear, easy to disassemble and assemble, and can be quickly checked and repaired in case of failure, reducing equipment downtime and improving production efficiency. In terms of general working media, electric flange ball valves can operate stably and reliably realize the transportation and control of media. In the face of highly oxidizing oxygen, highly corrosive hydrogen peroxide, and flammable and explosive methane and ethylene, special materials and sealing structures are used to effectively resist the erosion of the medium and ensure long-term stable operation under complex and dangerous working conditions.

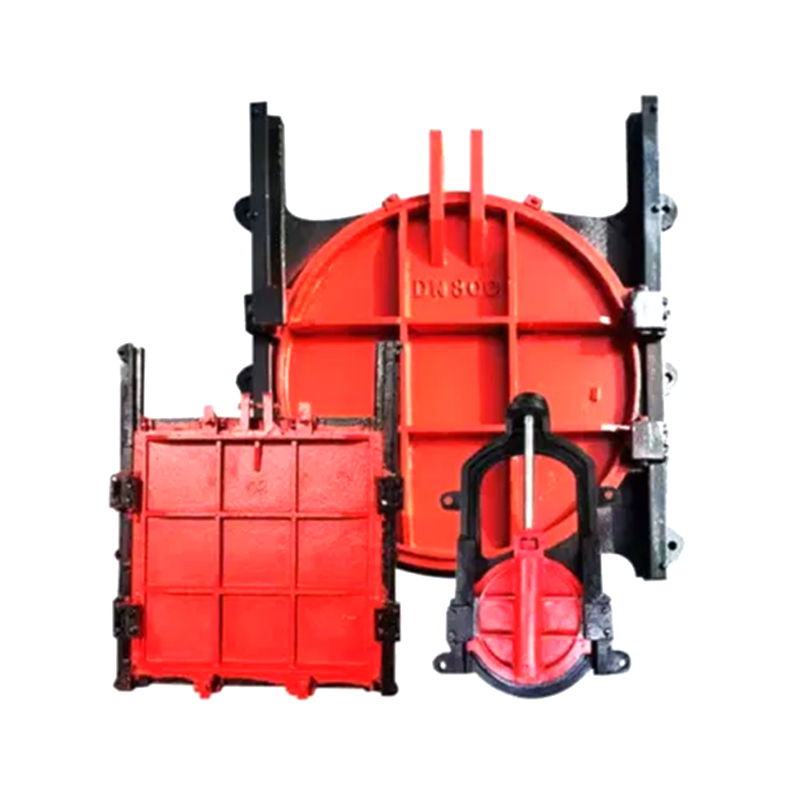

バルブ本体の構造

の electric flange ball valve with an integral valve body has a strong structural integrity and is obtained by one-time molding or integral processing during the manufacturing process. This valve body has no gaps or splicing, has excellent strength and sealing, can withstand high pressure, and effectively avoids medium leakage. In some occasions with extremely high requirements for sealing performance and large pressure fluctuations, such as high-pressure gas transmission pipelines and high-purity liquid transmission systems, electric flange ball valves with integral valve bodies are widely used. The modular valve body is composed of multiple independent modules, and each module can be flexibly designed and manufactured according to different usage requirements. This design makes the valve more convenient when assembling, repairing and replacing parts. When a module fails, only the module needs to be replaced in a targeted manner, without large-scale disassembly and repair of the entire valve, shortening the repair time and reducing maintenance costs. In projects that require frequent adjustments and upgrades to valves, the advantages of modular valve bodies are particularly prominent, and can better adapt to engineering needs at different stages.